Rubber wood (Hevea Brasiliensis) tree is one the most common and effective industrial plants in tropical countries. In Vietnam, it is considered to be one of the most national priority industrial products. Not counting on the latex - the initial product from the tree - wood from tree is also valuable and to be one of the most favorable materials for construction and wood-made industry. A hundred percent of Rubber wood trees in Vietnam are grown in plantations managed by both government and individuals.

Trees are cut down after finished its life cycle of about 25 years, among that is 20 years of latex providing. Then, logs are transported to sawmills, to be sawed and ripped into required sizes, called sawn timbers. These timbers will be steamed and treated by appropriate and health-safe chemicals to avoid any wood-eater worm and make it last longer.

CUTTING

CUTTING

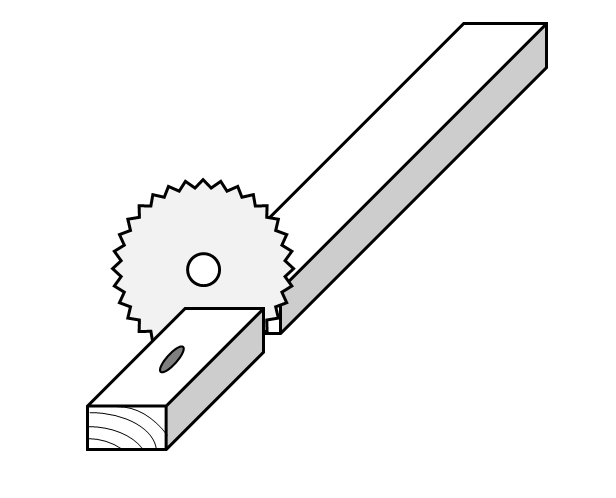

After receiving sawn timbers from sawmills, experienced workers will carefully cut away defects as well as cut into specific lengths. This cutting method will reject defected wood and avoid bending timbers. Only experienced and careful workers are authorized do this, who know how to reject bad wood in the most economical and effective way.

MOULDING

MOULDING

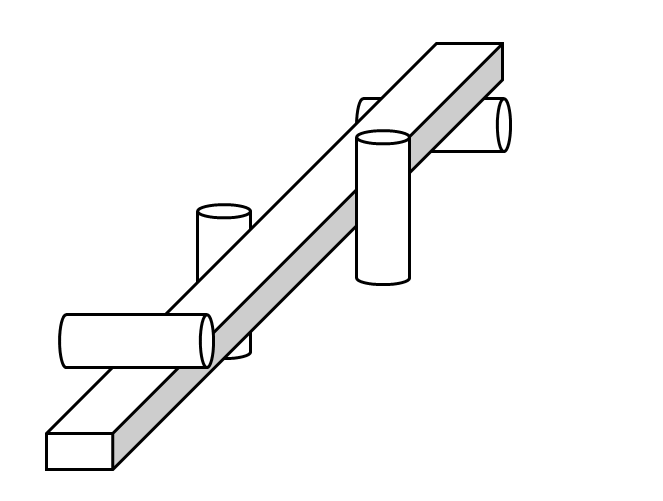

This section will help wood timber become square and smooth away from rough, uneven and coarse surfaces. Unlike cutting, this section requires larger and more modern machines, which can run automatically and massively. Only 4-side square and smooth timbers can be moved to next section, the rejected ones must be turned around and put into the machines again until they’re passed.

SELECTING

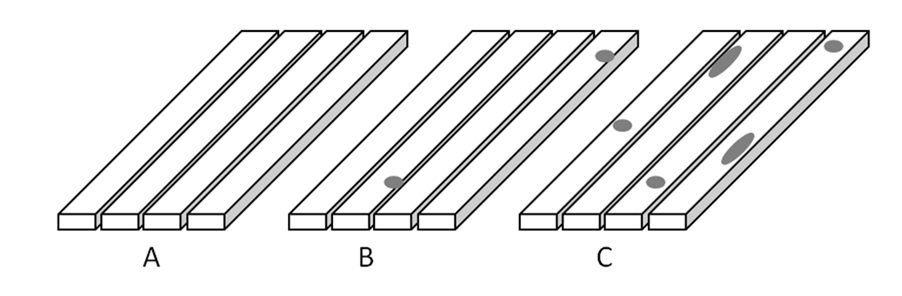

After going out of moulding machines, square and smooth timbers will be brought to selecting tables, where they are selected and sorted into many qualities, colors and sizes. As our experience, only lady workers are suitable for this section because of their natures of care, minute and endurance. Without these natures, they can not undertake sorting timbers into five qualities, seven colors and tens of sizes. These ladies are the ones who define the quality of the finished products afterwards.

After going out of moulding machines, square and smooth timbers will be brought to selecting tables, where they are selected and sorted into many qualities, colors and sizes. As our experience, only lady workers are suitable for this section because of their natures of care, minute and endurance. Without these natures, they can not undertake sorting timbers into five qualities, seven colors and tens of sizes. These ladies are the ones who define the quality of the finished products afterwards.

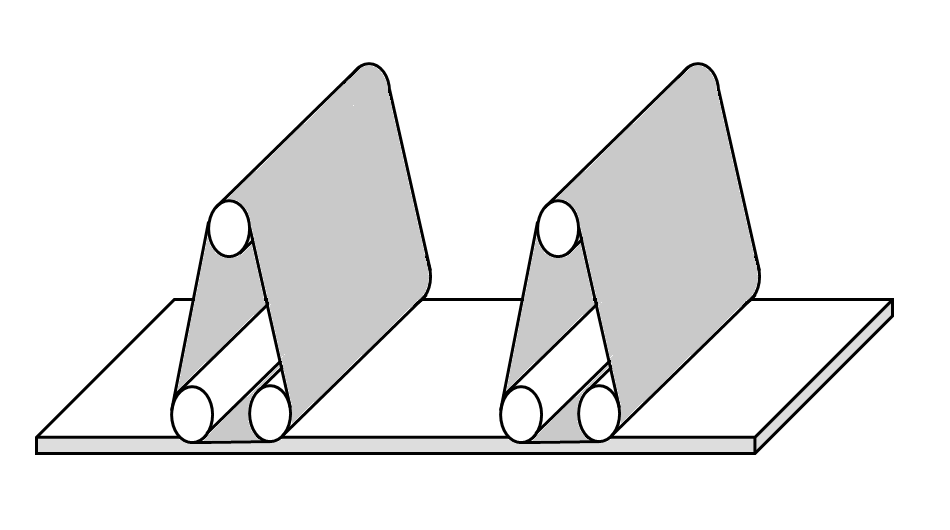

JOINTING

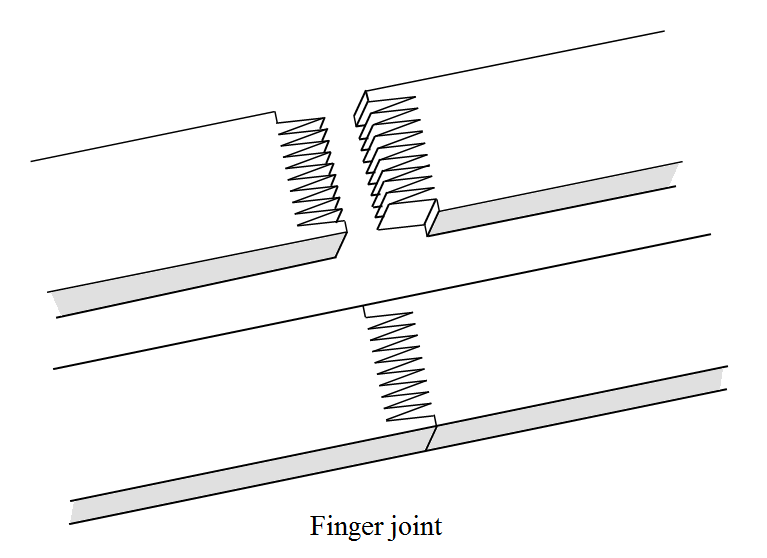

In order to make timbers to stick together into specific length, we put them through the Finger joint systems. Timbers will be formed into arrow-head shapes at its two ends, then glued and jointed together to make a long, straight and strong wood stick. The arrow-head shape ends will help maximize the contacting surfaces and then maximize the connecting strength. That will make the wood become stronger than itself. If you hit the wood stick with enough force to make it broken, you will find the broken wood but not the glued joints area. Only well-known and standard glues from Europe and Japan are used in this section.

In order to make timbers to stick together into specific length, we put them through the Finger joint systems. Timbers will be formed into arrow-head shapes at its two ends, then glued and jointed together to make a long, straight and strong wood stick. The arrow-head shape ends will help maximize the contacting surfaces and then maximize the connecting strength. That will make the wood become stronger than itself. If you hit the wood stick with enough force to make it broken, you will find the broken wood but not the glued joints area. Only well-known and standard glues from Europe and Japan are used in this section.

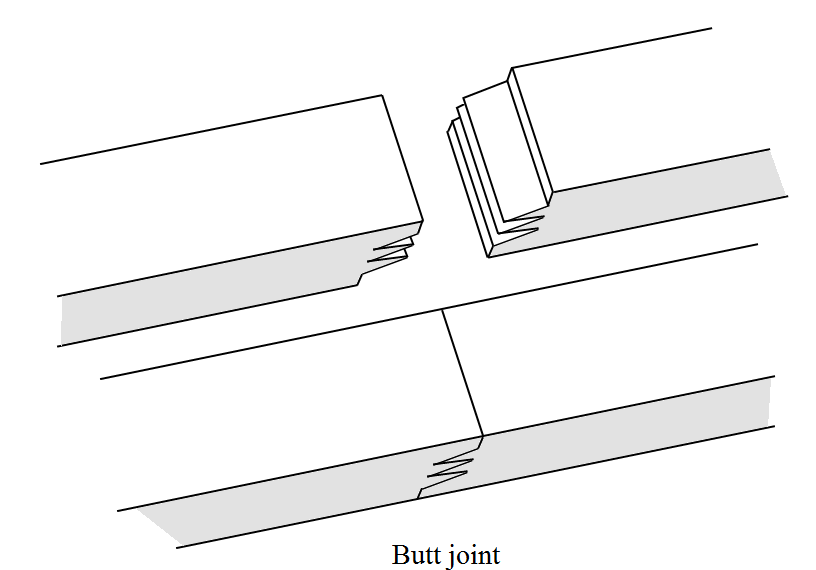

There are two types of joints, Finger joint and Butt joint.

Finger joint is the type in which the arrow-head shapes appear on the wider sides of the timber, and on the two surfaces of the panels.

Butt joint is the type in which the arrow-head shapes appear only on the smaller sides of the timber, and on the two sides of the panels. On the surface of Butt joint panel, only short and straight lines showed out.

COMPOSING

COMPOSING

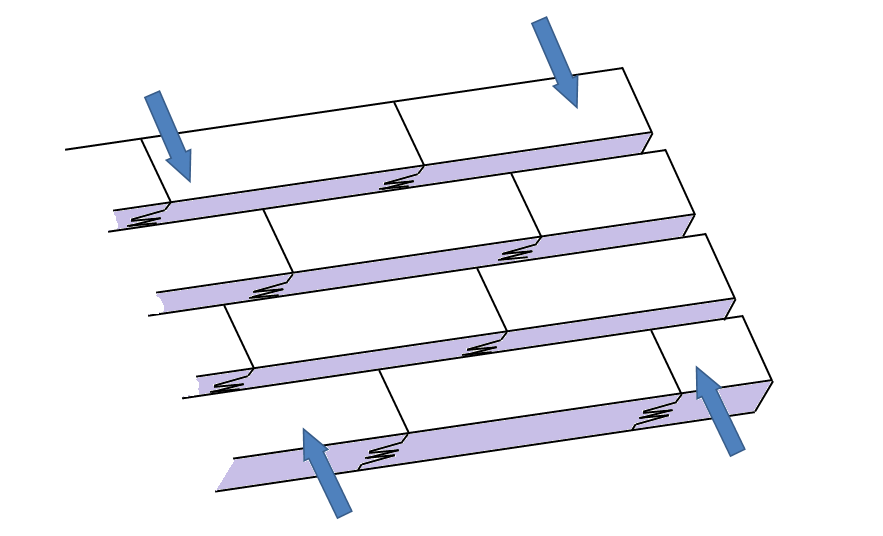

The panels are formed in this section by gluing and pressing the wood sticks together horizontally from their sides. Wood sticks are put through a glue roller to lay an adhesive layer on their sides. After that, glued wood sticks are laid onto the composing machines. This machine will press them from the sides and on the surfaces with appropriate pressure in a specific time to make sure that the glue is dried and perfectly adhesive. Same as Jointing section, only well-known and standard glues from Europe and Japan are used for the composing.

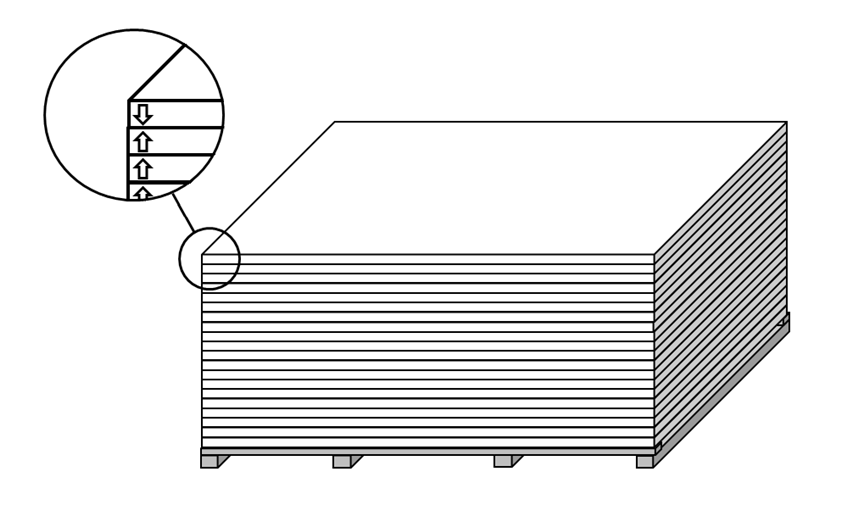

SEASONING

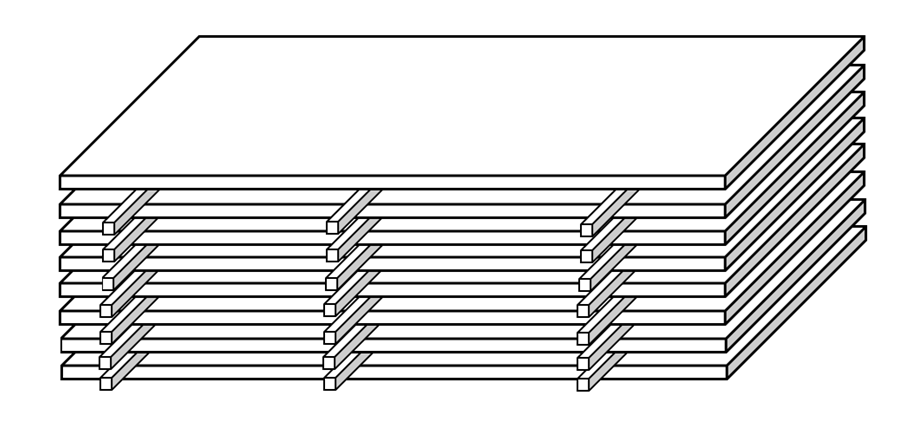

Although after the pressing time, the glue is dried and adhesive, but it’s not safe to put the panels to the next section immediately. Because the water containing inside the wood will make the glue wet again and reduce the adhesive strength. To avoid this, there’s a very simple method, put the panels at the dry, clear and windy areas. The panels are laid separately by small sticks so that the surfaces of the two next panels are not contacted to each other. This will help the air go through the two surfaces more easily and make the panels dry sooner. Normally, it takes about 5 to 7 days for the panels totally dried.

Although after the pressing time, the glue is dried and adhesive, but it’s not safe to put the panels to the next section immediately. Because the water containing inside the wood will make the glue wet again and reduce the adhesive strength. To avoid this, there’s a very simple method, put the panels at the dry, clear and windy areas. The panels are laid separately by small sticks so that the surfaces of the two next panels are not contacted to each other. This will help the air go through the two surfaces more easily and make the panels dry sooner. Normally, it takes about 5 to 7 days for the panels totally dried.

SANDING

Due to the requirement of the applications, the panel surfaces must be even, smooth and well-finished. To do this, the panels must be taken to the sanding section. Workers will put panels through the sanding machines several times to make sure the surfaces are well-finished and the thickness is exact and match to the requirements of the orders. There are many levels for the smoothness of the sanding finished surfaces, which is defined by the grid density of the sanding paper or silk. Normally, for the panels, we will finish with 240# or 320# sanding grid.

Due to the requirement of the applications, the panel surfaces must be even, smooth and well-finished. To do this, the panels must be taken to the sanding section. Workers will put panels through the sanding machines several times to make sure the surfaces are well-finished and the thickness is exact and match to the requirements of the orders. There are many levels for the smoothness of the sanding finished surfaces, which is defined by the grid density of the sanding paper or silk. Normally, for the panels, we will finish with 240# or 320# sanding grid.

INSPECTION AND REPAIRING

After sanding, some small defects will appear along with small technical faults. Qualified and skilled QC workers will inspect piece to piece and repair every defect appears. Thanks to QC careful work, every passed panel is smooth, clear of defects, exact thickness and sizes. Obviously, bad or out-of-standard panels will be rejected in this section.

After sanding, some small defects will appear along with small technical faults. Qualified and skilled QC workers will inspect piece to piece and repair every defect appears. Thanks to QC careful work, every passed panel is smooth, clear of defects, exact thickness and sizes. Obviously, bad or out-of-standard panels will be rejected in this section.

A standard checking process including

- Quality

- Jointing and composing technique

- Dimension

- Surfaces

- Moisture content ( 8 – 12%) PACKING

PACKING

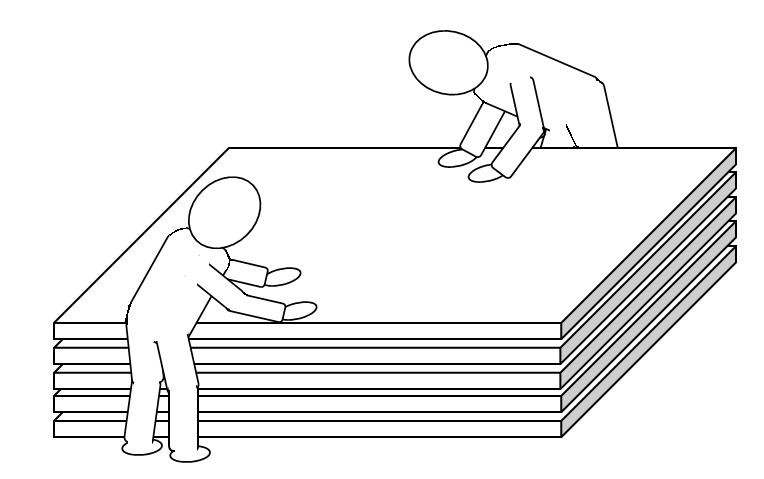

Most of our panels are for exporting. It usually takes about 10 to 30 days for transportation including loading at departure port, ocean travelling, moving at transshipment port and unloading at destination port. Among those is many-hour by-land transportation via trucks. Therefore, a standard, sustainable, full coverable and protectable packing method is required. We must ensure that panels will be delivered to end-users without any scratch or dent.

Most of our panels are for exporting. It usually takes about 10 to 30 days for transportation including loading at departure port, ocean travelling, moving at transshipment port and unloading at destination port. Among those is many-hour by-land transportation via trucks. Therefore, a standard, sustainable, full coverable and protectable packing method is required. We must ensure that panels will be delivered to end-users without any scratch or dent.

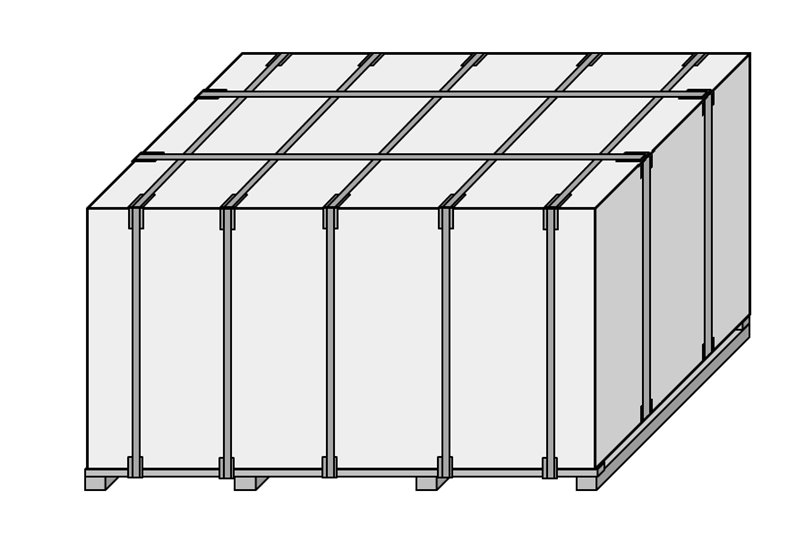

At our factory, finished panels are laid on a base pallet, which is strong, thick, steady and made by Rubber wood finger joint sticks. The bottom and the top panels are protectedby MDF or carton layers, which prevent the panels from forklifts or any other hard and sharp things during the loading and unloading process. Moreover, the top panel is laid up side down so that the better face will not be damaged in any case. Another layer of carton will be rounded vertically around the panel pile to protect their sides and edges. Then, steel or

At our factory, finished panels are laid on a base pallet, which is strong, thick, steady and made by Rubber wood finger joint sticks. The bottom and the top panels are protectedby MDF or carton layers, which prevent the panels from forklifts or any other hard and sharp things during the loading and unloading process. Moreover, the top panel is laid up side down so that the better face will not be damaged in any case. Another layer of carton will be rounded vertically around the panel pile to protect their sides and edges. Then, steel or  plastic straps are used to tight all up into a firm, square and unique bulk. Finally, a thin layer of PE will be the last cover to protect the carton from scratch and impact during the transportation.

plastic straps are used to tight all up into a firm, square and unique bulk. Finally, a thin layer of PE will be the last cover to protect the carton from scratch and impact during the transportation.

In some special cases, according to our customers’ requirement, each panel is wrapped individually by plastic or nylon before packing. That makes the panels 100% safe. This kind of packing is suitable for retailing at construction or DIY shops.